Project Details

Services

Deep Foundations

Deep Excavation

Pre-Cast Concrete

Structural Steel

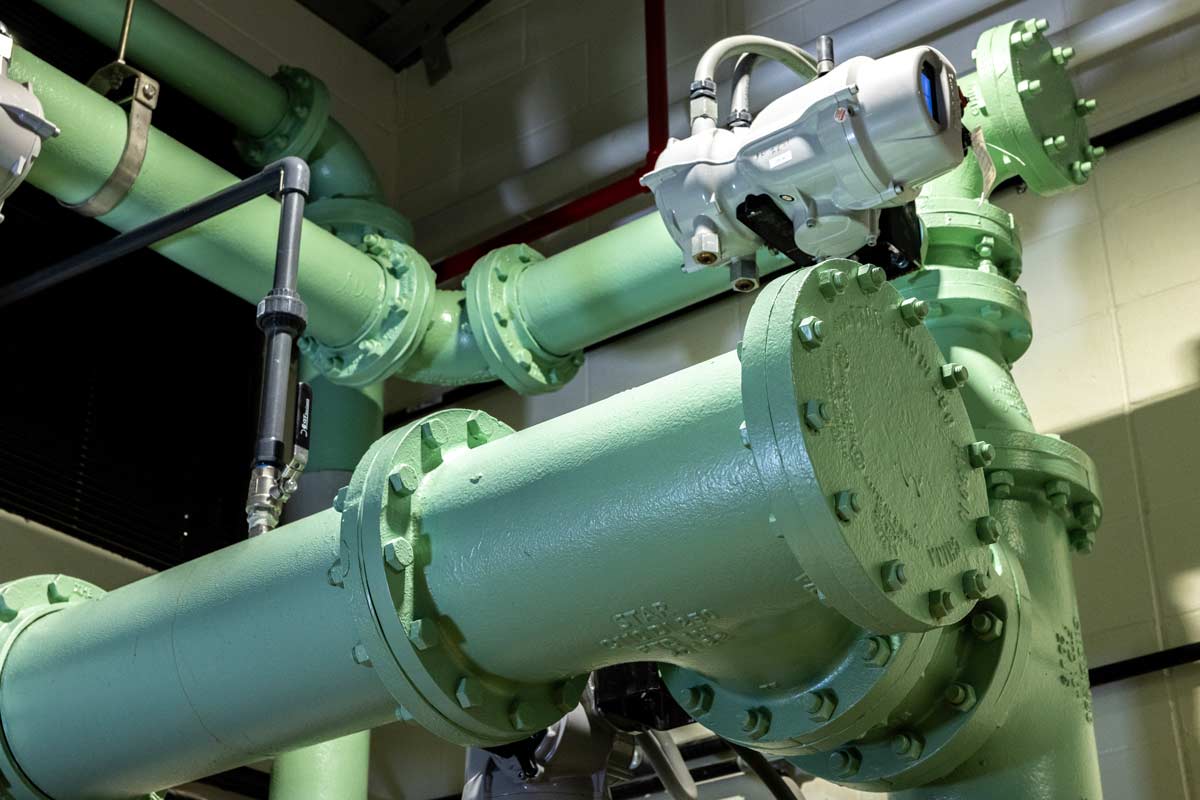

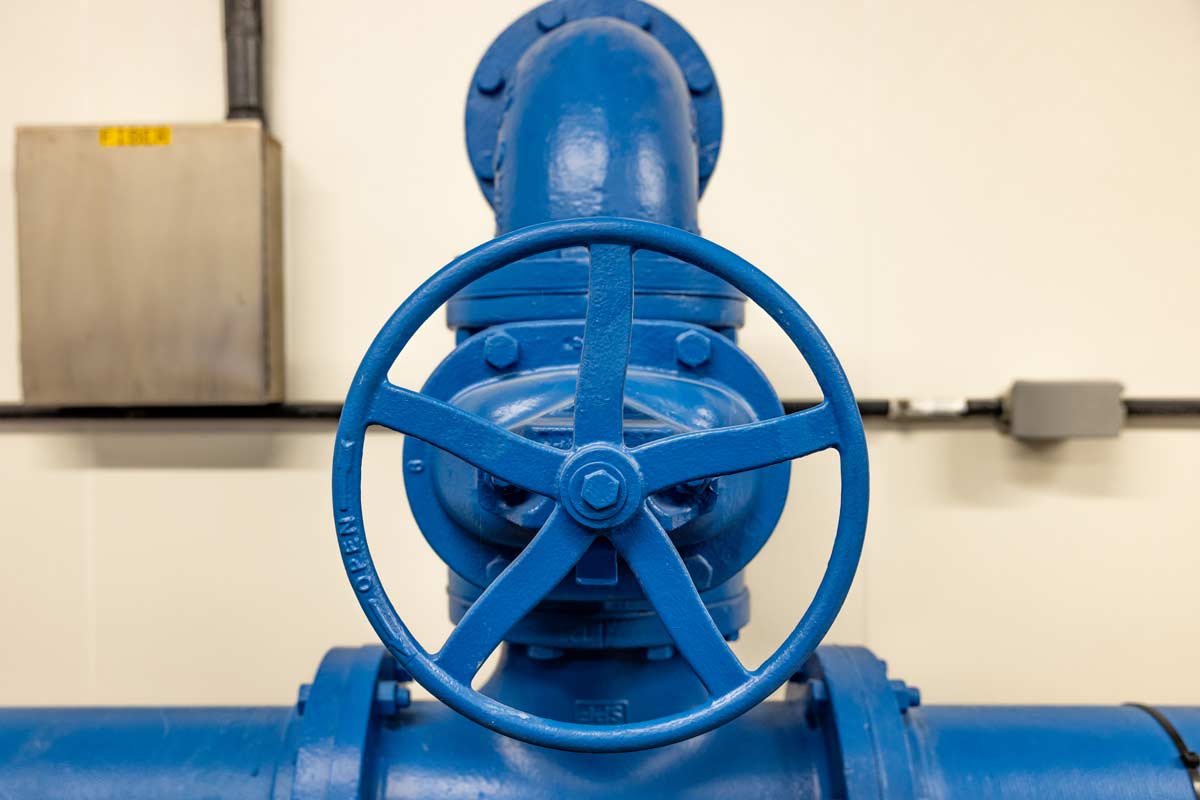

Process Piping

Equipment Installation

Project Team

City of Williamsburg (Owner)

HR Green (Engineer)

Budget

Final Construction Cost: $15.1M

Completion Date: 12/6/22

The City of Williamsburg faced a critical challenge: its existing water and wastewater treatment facilities were aging, undersized, and unable to meet new regulatory requirements.

The city’s water treatment plant, originally built in 1972 and last upgraded in 2001, relied on outdated iron and manganese filtration; its wastewater treatment plant struggled to handle peak flows during heavy rain events, and was at risk of failing to comply with federal permitting requirements. With a growing population and tightening environmental regulations, the city needed a comprehensive solution to ensure long-term water quality and reliability.

In collaboration with HR Green, WRH partnered with the City of Williamsburg to deliver a state-of-the-art water and wastewater treatment solution that not only addressed the community’s immediate concerns but also planned for future expansion. The project included the construction of a new 2.4 million gallon per day (MGD) reverse osmosis (RO) water treatment facility, housed in a 4,000-square-foot building. It features modern treatment technologies, chemical feed rooms, and critical infrastructure upgrades, ensuring the city’s residents have access to clean and safe drinking water. Additionally, modifications to the city’s four deep wells, high-service pumps, and reservoir improvements further enhanced operational efficiency.

Simultaneously, the city’s wastewater treatment system was overhauled with a new 1.35 MGD Sequencing Batch Reactor (SBR) plant. Designed for peak flow equalization and advanced nutrient removal capabilities, the new facility incorporated mechanical screening, grit removal, ultraviolet disinfection, and an effluent reuse system. WRH and HR Green worked closely with city officials, operational staff, and the public to ensure the project met both technical and community needs. Despite nationwide supply chain disruptions caused by the COVID-19 pandemic, the team adapted quickly, successfully managing construction schedules and minimizing cost impacts.

The result was a cutting-edge, environmentally sustainable water and wastewater treatment system that exceeded the community’s expectations. The new facilities not only meet current regulatory requirements but also position Williamsburg for future growth while reducing operational costs. The effluent reuse system alone is projected to save the city $50,000 annually in potable water consumption. With thoughtful planning, innovative design, and strong collaboration, WRH helped Williamsburg secure a resilient and long-lasting water infrastructure.